- #FREE CAD CAM SOFTWARE LINUX GENERATOR#

- #FREE CAD CAM SOFTWARE LINUX FULL#

- #FREE CAD CAM SOFTWARE LINUX VERIFICATION#

- #FREE CAD CAM SOFTWARE LINUX CODE#

- #FREE CAD CAM SOFTWARE LINUX FREE#

In application GCode and TPL view and edit.

#FREE CAD CAM SOFTWARE LINUX VERIFICATION#

GCode parsing, simulation, verification and annotation. Multi-threaded rendering can take advantage of multi-processor CPUs. Simulates cylindrical, conical, ballnose, spheroid and snubnose tool shapes. Fast 3-axis cut-workpiece simulation with 3D visualization. CAMotics should serve the highly technical user but remain simple and user friendly enough to support less techie types as well. And, if you need more help, we'll be happy to answer your questions via the discussion group.ĬAMotics aims to be a useful CNC simulation platform for the DIY and Open-Source community. By looking at the built-in examples and using the online documentation you'll be running your own simulations in no time. With the power to simulate your CNC tool paths you will avoid dangerous and expensive mistakes. It's fast, easy to use and best of all Open-Source and free. With CAMotics, you can simulate 3-axis GCode programs for CNCs and visualize the results in 3D. #FREE CAD CAM SOFTWARE LINUX FREE#

Licensing: Grbl is free software, released under the GPLv3 license. That means the controller will look up to 18 motions into the future and plan its velocities ahead to deliver smooth acceleration and jerk-free cornering.

#FREE CAD CAM SOFTWARE LINUX FULL#

Grbl includes full acceleration management with look ahead. Macro functions, variables, and most canned cycles are not supported, but we think GUIs can do a much better job at translating them into straight g-code anyhow. Arcs, circles and helical motion are fully supported, as well as, all other primary g-code commands. It accepts standards-compliant g-code and has been tested with the output of several CAM tools with no problems. It is able to maintain up to 30kHz of stable, jitter free control pulses. The controller is written in highly optimized C utilizing every clever feature of the AVR-chips to achieve precise timing and asynchronous operation. It will run on a vanilla Arduino (Duemillanove/Uno) as long as it sports an Atmega 328. Grbl is a no-compromise, high performance, low cost alternative to parallel-port-based motion control for CNC milling.

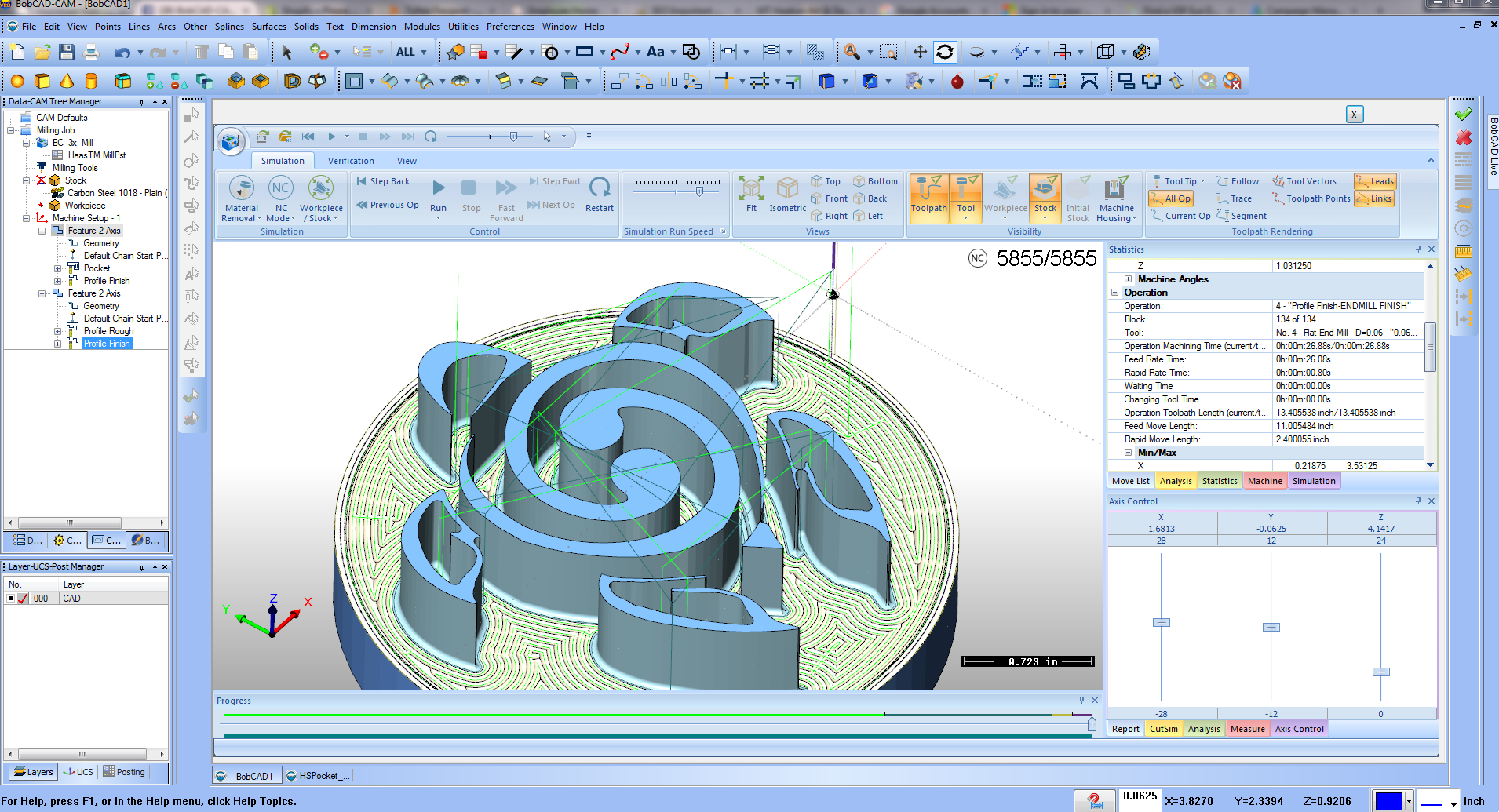

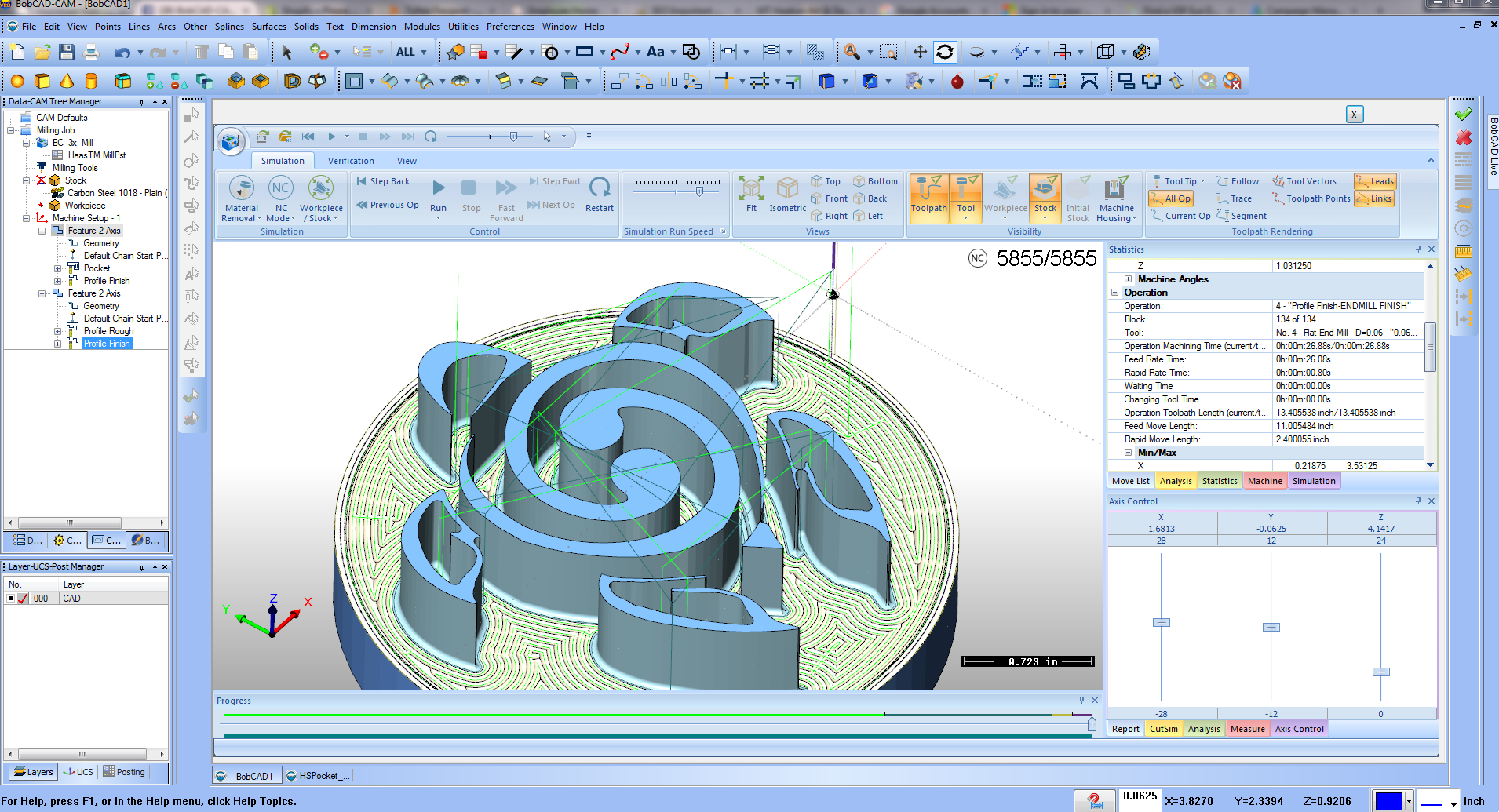

Setup toolpaths for CNC Routing, Laser cutting, Plasma Cutting and Dragknives. Import DXF/SVG/PNG/BMP/JPG/Gerber/Excellon files. OpenBuilds CAM is a web-based application for converting SVG, DXF and Bitmap drawings, to GCODE for use with your CNC, Laser, Plasma or Dragknife Machine and even help with your Firmware configuration. Flatten/Surface your spoilboard / stock. OpenBuilds CONTROL is an application for connecting to, and controlling, your CNC, Laser, Plasma or Dragknife machine. OpenBuilds CONTROL - Machine Interface Controller It is free software licensed under the GPL v3. Take a look at the Features page for a full list features. P圜AM supports a wide range of toolpath strategies for 3D models and 2D contour models. The resulting G-Code can be used with LinuxCNC or any other machine controller. It loads 3D models in STL format or 2D contour models from DXF or SVG files. #FREE CAD CAM SOFTWARE LINUX GENERATOR#

P圜AM is a toolpath generator for 3-axis CNC machining.

#FREE CAD CAM SOFTWARE LINUX CODE#

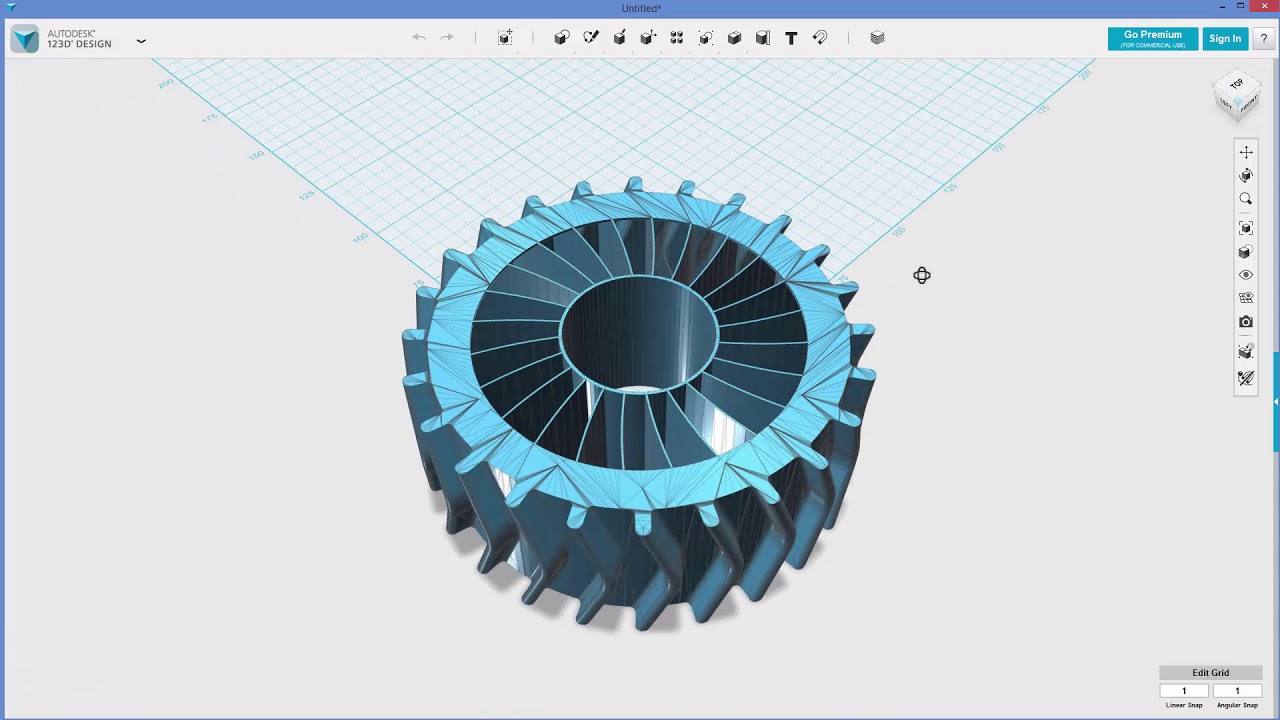

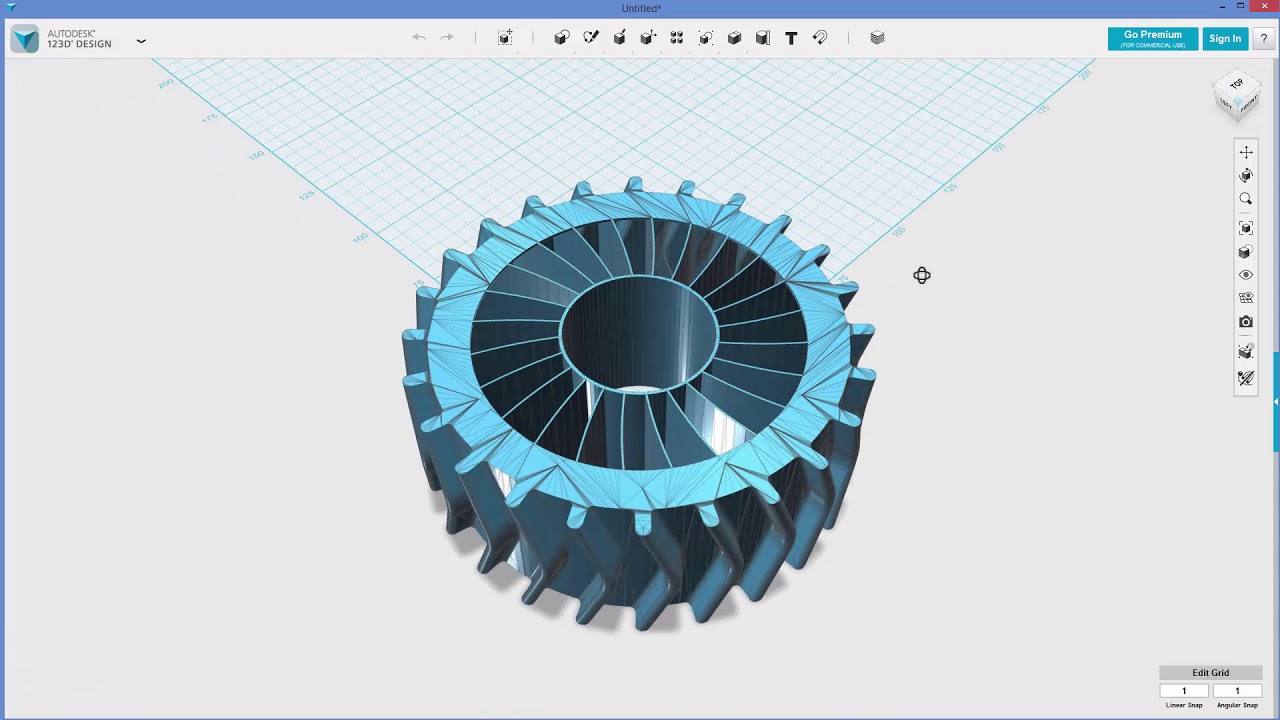

Full source code available under the terms of the GNU GPLv2 (General Public License version 2). Supports rigid tapping, cutter compensation, and many other advanced control features. Compatible with many popular machine control hardware interfaces. Accepts G-code input, drives CNC machines in response. Simple installation on Debian and Ubuntu, or via our Live/Install DVD/USB images. Runs under Linux (optionally with realtime extensions). It can drive milling machines, lathes, 3d printers, laser cutters, plasma cutters, robot arms, hexapods, and more. This step is called post processing there are different post processors available. Export the job with a g-code, matching to your machine. These Path objects use internal FreeCAD G-Code dialect, independent of the CNC machine. Tools are selected as required by the Job Operations.

This contains all the information required to generate the necessary G-Code to process the Job on a CNC mill: there is Stock material, the mill has a certain set of tools and it follows certain commands controlling speed and movements (usually G-Code).

A 3D model is the base object, typically created using one or more of the Part Design, Part or Draft Workbenches. The FreeCAD Path Workbench workflow creates these machine instructions as follows: Typically, instructions are a G-Code dialect. These produce real-world 3D objects on CNC machines such as mills, lathes, lasercutters, or similar. The Path workbench is used to produce machine instructions for CNC machines from a FreeCAD 3D model. FreeCAD - Path workbench - About FreeCAD

0 kommentar(er)

0 kommentar(er)